Zheflon® FL2606 PVDF — Extrusion Grade Copolymer for Wire and Cable Applications

- Model

- FL2606

Item specifics

- Features

- Copolymer, Medium and low viscosity

- Uses

- Wire and cable applications

- Forms

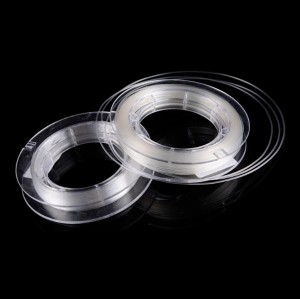

- Translucent white particles

Review

Description

Description

Zheflon® FL2606 is a medium to low melt viscosity PVDF copolymer with high purity and excellent chemical stability to most active substances and solvents. Excellent mechanical strength and toughness; High wear resistance, weather resistance, aging resistance. For the low permeability of most gases and liquids, it is easy to melt through the standard extrusion method. It is suitable for wire and cable applications.

Technical Specifications

Specifications | Range | Reference Standard | ||||

Melt Flow Rate(g/10min) | 3.0-9.0 | Load 5kg, 230℃, GB/T 3682 | ||||

Secondary Melting Point (℃) | 125-165 | GB/T19466 | ||||

Break Strength(Thickness2.00mm)(MPa) | ≥20 | GB/T 1040 | ||||

Elongation at Break(%) | ≥50 | GB/T 1040 | ||||

Yield Strength(Thickness2.00mm)(MPa) | ≥20 | GB/T 1040 | ||||

Elongation at Yield(%) | ≥5 | GB/T 1040 | ||||

Whiteness | ≥40 | GB/T 2913 | ||||

Yellowness | ≤10 | HB/T 3862 | ||||