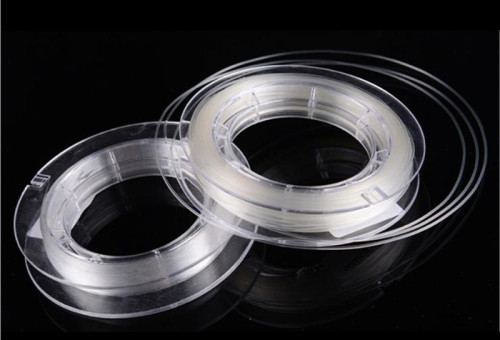

Zheflon® FL2005 PVDF- For Fishing line

- Model

- FL2005

Item specifics

- Features

- Homopolymer, medium melt viscosity

- Uses

- Fishing line, OK line, monofilament

- Forms

- White translucent particles

- Grade

- Extrusion grade

Review

Description

Zheflon® FL2005 is a medium-viscosity grade polyvinylidene fluoride homopolymer with high purity. Important properties include excellent chemical resistance to most aggressive substances and solvents, excellent mechanical strength and toughness, high abrasion resistance, high temperature capabilities, excellent aging resistance, low permeability to most gases and liquids and easily melt-processed by standard methods of squeeze and molding.

General | ||

Features | Homopolymer, medium melt viscosity | |

Uses | Fishing line, OK line | |

Forms | White translucent particles | |

Items | Typical Value FL2005 | Test Method |

Physical Properties | ||

Density(g/cc) | 1.76~1.79 | ASTM D792 |

Melt Flow Rate(g/10min) | 1.5~2.5 | Load 10kg,230℃,ASTM D1238 |

Melt viscosity(Kps) | 21~25 | Shear Rate 100 1/s,ASTM D3835 |

Water Absorption(%)(Time 24 hr) | ≤0.010 | ISO 62 |

Molecular Properties | ||

Molecular weight(Da) | 420,000~460,000 | GPC,DMF,ISO 16014 |

Intrinsic viscosity(dl/g) | 1.25~1.35 | 30℃,DMAC |

Molecular weight distribution | 1.8-2.3 | GPC,DMF,ISO 16014 |

Mechanical Properties | ||

Tensile Modulus(Thickness2.00mm)(MPa) | 1800~2500 | 1.0mm/min,ASTM D638 |

Flexural Modulus(Thickness2.00mm)(MPa) | 1700~2500 | 2.0mm/min,ASTM D790 |

Yield Strength(Thickness2.00mm)(MPa) | 50.0~57.0 | 50mm/min,ASTM D638 |

Break Strength(Thickness2.00mm)(MPa) | 20.0~50.0 | 50mm/min,ASTM D638 |

Elongation at Yield(%) | 5.0~10 | 50mm/min,ASTM D638 |

Elongation at Break(%) | 20~50 | 50mm/min,ASTM D638 |

Hardness, Shore D(Thickness2.00mm) | 75~80 | ASTM D2240 |

Thermal Properties | ||

Melting Point(℃) | 169~173 | ASTM D3418 |

Crystallization temperature(DSC peak)(℃) | 137~144 | ASTM D3418 |

Glass Transition Temp, Tg(℃) | -32 | ASTM E1356 |

Decomposition Temperature(℃) | 375 | 1% wt. loss / in air |

Vicat softening point(℃) | 135~145 | ASTM D1525 |

Heat distortion temperature 1.8 MPa (Thickness 4.00mm)(℃) | 100~120 | After annealing 150℃,16h ASTM D648 |

Electrical Performance | ||

Surface resistance(ohm) | ≥1.00E+14 | Voltage<1V,After 2 min—500V ASTM D257 |

Resistivity(ohm·cm) | ≥1.00E+14 | Intensity=10mA,After 2 min@23℃ ASTM D257 |

Dielectric strength(Thickness 1.00mm,23℃)(KV/mm) | 20~25 | ASTM D149 |

Dielectric constant(1kHz,23℃) | 7.0~10.0 | ASTM D150 |

Combustion performance | ||

UL Flammability rating(0.100mm) | V-0 | UL94 |

Oxygen Index(3.00mm) | 44% | ASTM D2683 |