PVDF Boosts Hangzhou Asian Games

- Share

- Issue Time

- Oct 18,2023

Summary

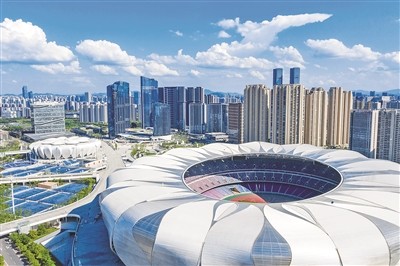

PVDF powder coating was used in many of the stadiums. All of the competition venues for the Hangzhou Asian Games have been designed with a "low carbon philosophy".

Recently, the Hangzhou Asian Games were in full swing. The Hangzhou government has invested heavily in the construction of a number of stadiums in preparation for this major event. All of the competition venues for the Hangzhou Asian Games have been designed with a "low carbon philosophy", which has been incorporated into all aspects of planning, design, construction and operational management. The selection of environmentally friendly materials and technologies to minimise the impact on the environment will make the Hangzhou Asian Games a prominent representative of the "Green Asian Games".

PVDF powder coating was used in many of the stadiums. This option is used on curtain walls, ceilings, aluminium doors and windows in the stadiums, especially to protect them from strong UV rays. And the PVDF coating has the excellent ability to maintain the colour of the surfaces for 10 to 30 years, ensuring the stability of the surface material. This allows our stadiums to not only withstand the test of time and the environment, but also to maintain a long-lasting lustre.

PVDF:Polyvinylidene Fluoride (PVDF) is a polymer. It is prepared by polymerising vinylidene fluoride monomer.The molecular structure of PVDF contains the elements carbon, hydrogen and fluorine, so it is a fluoropolymer.

The molecular structure of PVDF is as follows:-(-CH2-CF2-)n-

PVDF has important applications in engineering, chemical, medical and other fields due to its chemical stability, corrosion resistance, high temperature resistance and electrical insulation properties.

PVDF Properties:

Chemical Properties:PVDF is a polymer composed of fluorine and hydrogen, with a primary chemical structure of -(CH2-CF2)-n. It exhibits excellent chemical resistance, resistance to UV radiation, and high temperature stability due to its high fluoride content.

Thermoplastic: PVDF is a thermoplastic material, meaning that it can be heated and cooled many times over a range of temperatures without decomposing. This makes it suitable for processes such as thermoforming and injection moulding.

Electrical Insulation: PVDF is an excellent electrical insulator, so it is commonly used in wires and cables, battery diaphragms, and electronic devices to stop current leakage.

Heat Resistance: PVDF is able to maintain its physical properties at relatively high temperatures, typically withstanding temperatures ranging from -40°C to 150°C.

Weathering: PVDF is widely used in architectural and exterior coatings due to its excellent weathering resistance to UV rays, natural weather and chemical corrosion.

Biocompatibility: PVDF also has applications in the medical field as it is highly biocompatible and can be used for medical devices, artificial organs and biomedical research.

Heart to Heart,@Future